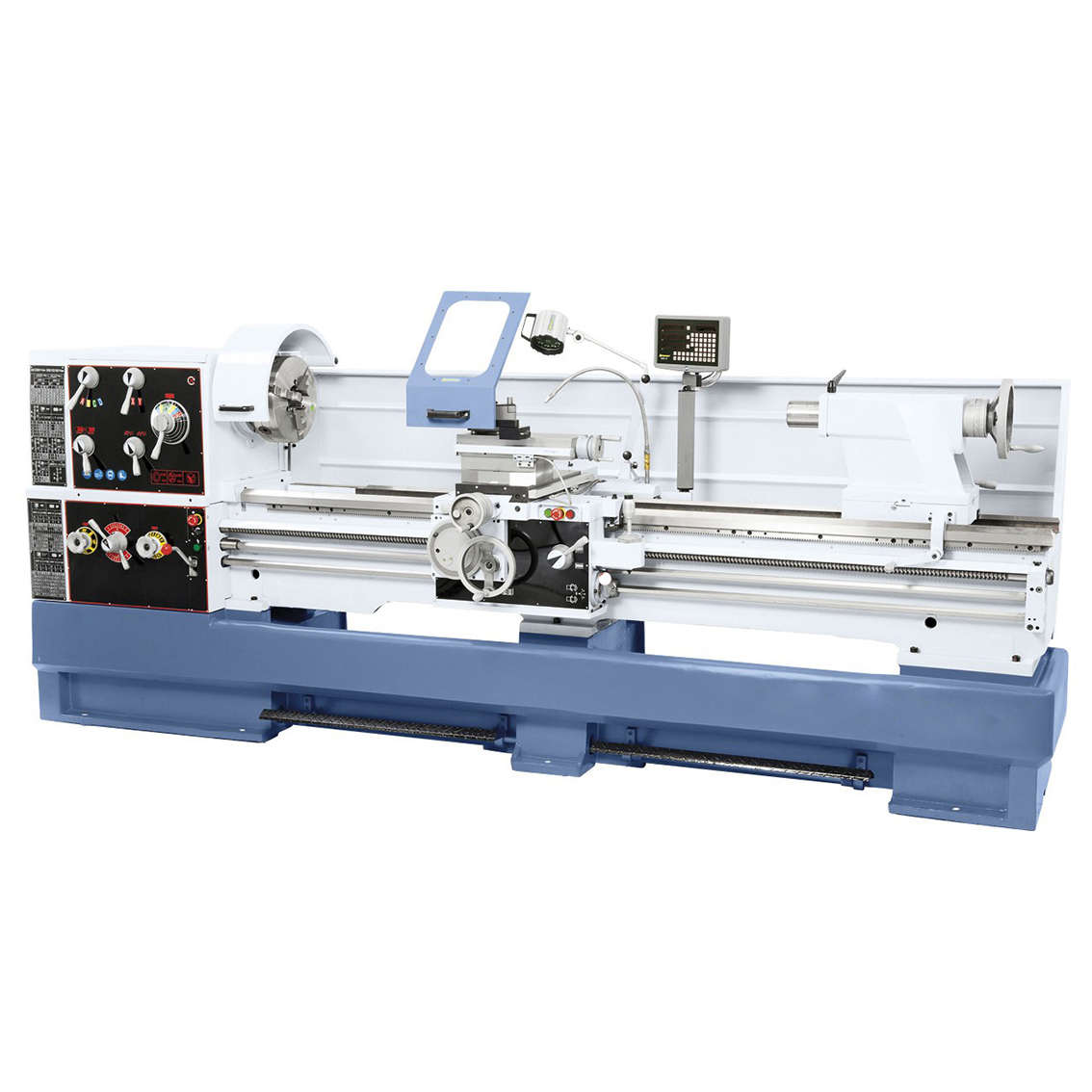

Cav Hlau Tshuab dhos C6280Y

Nta

1.Precision av

2. Clutched taub hau Tshuag

3. CE-ua raws

4. Kev nyab xeeb torque limiting ntaus ntawv rau cov ntsia hlau txhuas

5. Kev ruaj ntseg overload clutch rau feedrod

6. Rapidtraverse (yeem)

7. Lub ntsiab spindle txhawb ntawm 2 cov ntsiab lus nrog predision taper cov menyuam bearings

8. 2500-3000mm Tshuab dhos nrog ua raws li chip cuard

Specifications

| Qauv | C6280 xyoo | |

| CAPACITY | Hla lub txaj | 800 |

| Swing hla hla swb | 545 ib | |

| Swing nyob rau hauv qhov sib txawv | 1000 | |

| Siv tau ntev ntawm qhov sib txawv | 2800 | |

| Max.ntev ntawm workpiece | 1000/1500/2000/3000 | |

| Dav ntawm bedways | 400 hli | |

| HADSTOCK | Spindle qhov ntswg | ISO--c11 lossis ISO--D11 |

| Spindle bore | 103 hli (4 ") | |

| Ntau yam ntawm spindle speeds / kauj ruam | 18 (ccw/18) 9-1275rpm 6 (cw/6£ © 16-816rpm | |

| NYIAJ THIAB THOV | Max.kev mus ncig ntawm compound so | 110 hli / |

| Max.taug kev hla swb | 325 hli / | |

| Longitudinal pub ntau yam | 12mm los yog 2 TPI | |

| Tshooj ntawm cov cuab yeej | 32 * 32mm | |

| Longitudinal pub ntau yam | 72 yam 0.073-4.066 mm / rev | |

| Hla pub ntau yam | 72 yam 0.036-2.033 mm / rev | |

| Metric threads muaj ntau yam | 72 yam 0.5-112 mm | |

| Inch threads ntau yam | 72 yam 56-1/4 nti | |

| Module threads ntau yam | 36 yam 0.5-7 | |

| Diameter threads muaj ntau yam | 36 yam 56-4D.P | |

| TAIL STOCK | Dia.ntawm lub tes tsho tailstock | 90mm ua |

| Morse taper ntawm lub tes tsho tailstock | Morse No.6 | |

| Kev mus ncig ntawm lub tes tsho tailstock | 150 hli | |

| Hla kev hloov kho ntau yam | 10 hli | |

| MOTOR | Lub zog ntawm lub cev muaj zog | 7.5kw los yog 11kw |

| Lub zog ntawm lub cev muaj zog ceev ceev | 250 wb | |

| Lub zog ntawm lub twj tso kua mis coolant | 125 wb | |

| Lub zog ntawm lub twj tso kua mis coolant | 220v, 380v, 440v (50HZ 60HZ) | |

| Packing Loj (L * W * H) | 1000 hli | 3820 * 1300 * 2100 hli |

| 1500 hli | 3320 * 1300 * 2100 hli | |

| 2000 hli | 3820 * 1300 * 2100 hli | |

| 3000 hli | 4820 * 1300 * 2100 hli | |

Peb cov khoom tseem ceeb suav nrog CNC tshuab cuab yeej, machining center, lathes, milling tshuab, drilling tshuab, sib tsoo tshuab, thiab lwm yam.Qee yam ntawm peb cov khoom muaj lub teb chaws patent txoj cai, thiab tag nrho peb cov khoom tau tsim zoo kawg nkaus nrog cov khoom zoo, kev ua haujlwm siab, tus nqi qis, thiab kev ruaj ntseg zoo heev.Cov khoom tau raug xa tawm mus rau ntau tshaj 40 lub teb chaws thiab cheeb tsam thoob plaws tsib lub teb chaws.Raws li qhov tshwm sim, nws tau nyiam cov neeg siv khoom hauv tsev thiab txawv teb chaws thiab txhawb nqa cov khoom muag sai Peb txaus siab rau kev nce qib thiab txhim kho ua ke nrog peb cov neeg siv khoom.Peb lub zog muaj zog, peb cov cuab yeej siv siab heev, peb cov cuab yeej siv tau siab heev, peb cov kev tswj xyuas zoo yog zoo meej thiab nruj, thiab peb cov khoom tsim thiab tshuab computerized.Peb tos ntsoov yuav tsim kom muaj kev sib raug zoo ntawm kev lag luam nrog cov neeg siv khoom thoob ntiaj teb.