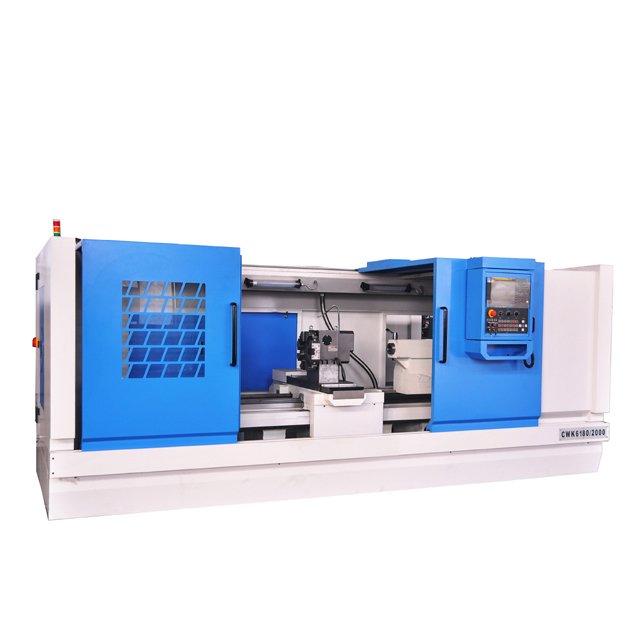

CAK6180 CNC Kab rov tav CNC tshuab dhos tshuab

Nta

Tsis siv neeg 3 kauj ruam hloov ceev

Infinitely variable ceev hloov rau spindle.

High rigidity thiab raug

1.1Cov cuab yeej siv tshuab no yog cov khoom lag luam paub tab feem ntau xa tawm los ntawm lub tuam txhab.Lub tshuab tag nrho muaj cov qauv compact, zoo nkauj thiab zoo nkauj tsos, loj torque, siab rigidity, ruaj khov thiab txhim khu kev qha kev ua tau zoo thiab zoo heev raug tuav.

1.2 lub optimized tsim ntawm headbox txais peb lub zog thiab stepless ceev tswj nyob rau hauv lub zog;Nws yog tsim rau tig disc thiab ncej qhov chaw.Nws tuaj yeem ua cov kab ncaj nraim, arc, metric thiab British xov thiab ntau lub taub hau xov.Nws yog tsim rau tig disc thiab ncej qhov chaw nrog txoj kev zoo thiab siab precision yuav tsum.

1.3 lub tshuab cuab yeej qhia kev tsheb ciav hlau thiab lub eeb qhia kev tsheb nqaj hlau yog cov lus qhia nyuaj ua los ntawm cov khoom tshwj xeeb.Tom qab high-frequency quenching, lawv yog super nyuaj thiab hnav-resistant, ruaj thiab muaj kev ua tau zoo raug tuav.

1.4 tus lej tswj qhov system txais Guangshu 980tb3 tus lej tswj qhov system, thiab txais yuav cov khoom lag luam nto moo thiab zoo zoo pob ntsia hlau thiab high-precision ntsia hlau pas nrig bearing.

ib tug taw tes tsib Lub yuam tsis siv neeg lubrication ntaus ntawv yog siv rau taag-point thiab kom muaj nuj nqis lubrication ntawm cov hlau lead ntsia hlau thiab qhia rail ntawm txhua lub lubrication point.Thaum muaj lub xeev txawv txav lossis tsis muaj roj txaus, lub teeb liab ceeb toom yuav raug tsim tawm.

1.5 Ascraping ntaus ntawv yog ntxiv rau hauv phau ntawv qhia kev tsheb ciav hlau los tiv thaiv txoj kev tsheb ciav hlau los ntawm kev corroded los ntawm hlau chips thiab coolant thiab pab txhawb kev tu cov hlau chips.